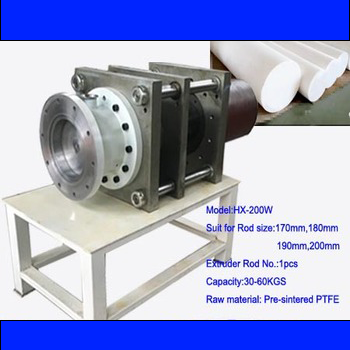

The HX-200W Horizontal Ram Extrusion Machine is a specialized piece of equipment designed for the production of PTFE (Polytetrafluoroethylene) rods. PTFE is a high-performance thermoplastic known for its excellent chemical resistance, high-temperature stability, and non-stick properties, making it ideal for various industrial applications. This machine is widely used in industries where precision and durability are critical, such as in the production of seals, gaskets, bearings, and electrical insulation.

Function and Features

The HX-200W Horizontal Ram Extrusion Machine works by extruding PTFE material through a die under controlled pressure and temperature conditions to create rods of consistent diameter and length. The machine’s horizontal ram design provides enhanced stability during the extrusion process, ensuring high-quality and uniform output. It is designed to handle high-viscosity materials like PTFE, which require specific pressure and temperature control for optimal extrusion.

Key features of the HX-200W include:

- Precision Extrusion: Produces PTFE rods with consistent dimensions and smooth surfaces.

- Efficient Process: Capable of handling large volumes of material with high throughput.

- Durability: Built with robust components for long-lasting performance.

- Versatility: Suitable for various applications, including high-temperature seals and electrical components.

Applications

The HX-200W Horizontal Ram Extrusion Machine is primarily used in the production of PTFE rods for a variety of industries:

- Chemical Processing: Manufacturing seals, bearings, and bushings.

- Aerospace: Producing insulation for wires and cables.

- Automotive: Creating components that require high chemical and thermal resistance.

In summary, the HX-200W Horizontal Ram Extrusion Machine is an essential tool for producing high-quality PTFE rods, offering precision, efficiency, and versatility for various industrial applications.

Leave A Comment

You must be logged in to post a comment.