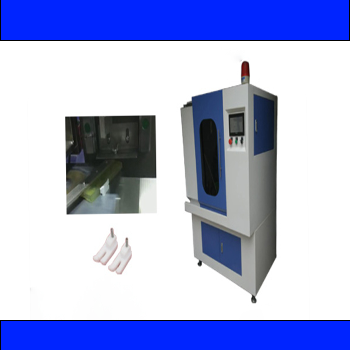

The PTFE presser foot molding machine is a specialized piece of equipment used to create presser feet made from PTFE (Polytetrafluoroethylene) material. PTFE is widely known for its non-stick, high-temperature, and chemical-resistant properties, making it ideal for specific industrial applications. This molding machine is designed to precisely mold PTFE into components like presser feet for various industries, such as sewing, textile, and manufacturing.

Molding Process of PTFE Presser Foot

The PTFE presser foot molding machine uses a combination of heat and pressure to mold PTFE material into a precise shape. The PTFE resin is first heated until it reaches its moldable state, and then it is injected or pressed into a mold. The mold is designed to create the specific shape of a presser foot, which is then cooled and ejected from the machine. This process ensures that the presser foot has the desired dimensions and structural properties.

Uses in the Textile Industry

One of the primary uses of PTFE presser foot molding machines is in the textile and garment industries. PTFE presser feet are used in sewing machines because the material has excellent non-stick properties, which help prevent fabric from sticking to the presser foot during sewing. This is especially important for delicate fabrics and high-speed sewing operations, as PTFE ensures smooth, friction-free sewing.

Durability and Chemical Resistance

The PTFE presser foot molding machine produces parts that offer high durability, resistance to chemicals, and high-temperature stability. These features are essential in environments where the presser foot is exposed to harsh chemicals, high heat, or continuous use, such as in automotive manufacturing or industrial textile processing.

Conclusion

In conclusion, PTFE presser foot molding machines are crucial for producing high-performance presser feet used in sewing, textile, and industrial applications. Their ability to create parts that are non-stick, durable, and resistant to high temperatures and chemicals makes them invaluable in various manufacturing processes.

Leave A Comment

You must be logged in to post a comment.