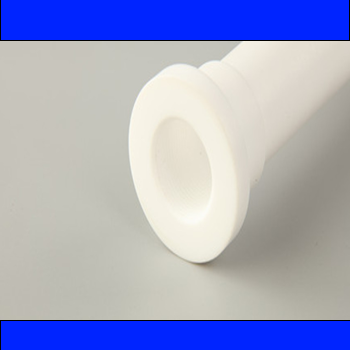

Polytetrafluoroethylene (PTFE) mold tubes are versatile components used in various industrial processes, particularly in the manufacturing of electrical cables and high-temperature applications. These tubes offer excellent performance due to their unique properties, such as chemical resistance, high-temperature stability, and electrical insulation. Below are the primary functions of PTFE mold tubes:

Electrical Insulation

- Prevention of Electrical Current Flow: PTFE mold tubes are widely used for insulating wires and cables. The high dielectric strength of PTFE ensures that electrical current is confined to the desired path, preventing short circuits and electrical failures.

- Enhanced Safety: Due to their non-conductive nature, PTFE mold tubes provide safety by reducing the risk of electrical hazards in cables and electrical devices.

High-Temperature Resistance

- Heat Protection: PTFE mold tubes can withstand extreme temperatures (up to around 260°C or 500°F), making them ideal for applications in high-temperature environments, such as aerospace, automotive, and industrial settings.

- Thermal Insulation: The mold tube serves as an effective thermal barrier, protecting sensitive components from heat damage.

Chemical Resistance

- Protection in Harsh Environments: PTFE is chemically inert and resistant to a wide range of corrosive substances, including acids, bases, and solvents. PTFE mold tubes ensure that electrical cables and components remain intact in harsh chemical environments.

- Long-Lasting Durability: The chemical resistance of PTFE increases the longevity and reliability of the components it insulates.

Mechanical Protection

- Wear Resistance: The mold tube acts as a protective shield against abrasion and mechanical damage, especially in dynamic applications where components experience friction.

In summary, PTFE mold tubes are primarily used for insulation, thermal protection, chemical resistance, and mechanical durability, making them essential in a variety of industries, particularly those requiring high-performance materials.

Leave A Comment

You must be logged in to post a comment.