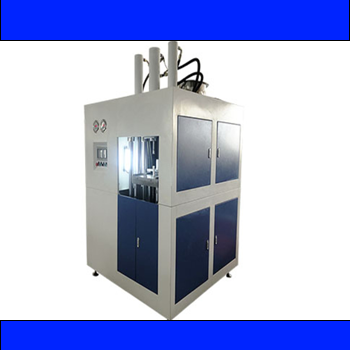

A PTFE molding machine is a crucial piece of equipment used in the manufacturing of Polytetrafluoroethylene (PTFE) products. Once the molding machine is assembled, tested, and prepared, it is carefully packaged and made ready for shipment to customers or production facilities. Here’s a look at the process involved in preparing a PTFE molding machine for shipment.

1. Final Assembly and Testing

Before shipment, the PTFE molding machine undergoes final assembly to ensure all components are securely fitted. This includes installing the molding chamber, hydraulic systems, temperature controls, and electrical components. After assembly, the machine is rigorously tested for functionality, ensuring that it meets all operational standards. Testing typically includes checks for pressure, temperature regulation, and mold alignment to ensure the machine will perform optimally in its future operations.

2. Cleaning and Inspection

Once testing is complete, the machine is thoroughly cleaned to remove any residue from manufacturing or testing procedures. Any parts that may have been exposed to dust, oil, or other contaminants are cleaned to maintain the integrity of the machine. Additionally, a final inspection is carried out to identify any potential defects or issues that might have been overlooked. Only after passing the inspection is the machine deemed ready for shipment.

3. Packaging for Shipment

To prevent any damage during transit, the PTFE molding machine is carefully packaged. Fragile components, such as electrical panels, are protected with foam padding or other cushioning materials. The machine is then securely fastened to a pallet or wooden crate, and a protective covering is added to shield it from dust, moisture, or impact during transportation.

4. Shipping Documentation

All necessary shipping documents, including the bill of lading, invoice, and warranty details, are prepared and included with the shipment. This ensures smooth customs clearance and provides the customer with essential information for future service or maintenance.

Conclusion

Once assembled, tested, cleaned, and packaged, the PTFE molding machine is ready for shipment to its final destination. With proper handling and thorough documentation, the machine can be transported safely, ensuring that it is ready to be put to work upon arrival.

Leave A Comment

You must be logged in to post a comment.