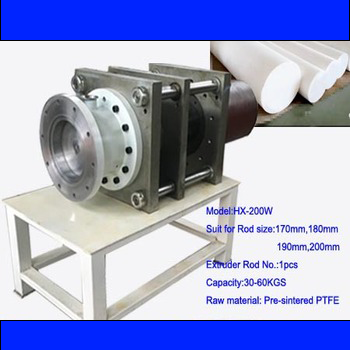

The HX-200W Horizontal Ram Extrusion Machine is designed specifically for the production of PTFE (Polytetrafluoroethylene) rods, offering precision, efficiency, and high-quality results. This machine is integral to manufacturing PTFE rods used in a wide variety of industrial and commercial applications due to its specialized features and capabilities. Below are the key properties and features of the HX-200W machine.

1. Design and Structure

- Horizontal Layout: The horizontal configuration of the HX-200W machine allows for a stable extrusion process, which ensures consistency in rod production.

- Durability: Constructed with robust materials, the machine is built to withstand the high-pressure forces involved in PTFE rod extrusion.

- Compact Size: The machine has a compact design, making it suitable for smaller production spaces while maintaining high performance.

2. Extrusion Efficiency

- High Extrusion Pressure: The HX-200W can generate high extrusion pressure, which is essential for processing PTFE, a material known for its toughness and resistance to deformation.

- Precise Control: The machine features precise control systems for temperature and pressure, ensuring optimal processing of PTFE material for uniform rods.

3. Temperature Management

- Heating System: The HX-200W is equipped with an advanced heating system to keep the PTFE material at the ideal extrusion temperature.

- Temperature Uniformity: The system ensures uniform heat distribution to prevent material inconsistencies, ensuring smooth, high-quality extrusion.

4. Safety and Operation

- User-Friendly Interface: The machine is designed with an intuitive control panel, making it easy for operators to adjust parameters such as speed, pressure, and temperature.

- Safety Features: The HX-200W includes built-in safety mechanisms to prevent overheating and material mishandling, ensuring safe operation.

5. High-Quality Product Output

- Precision Rods: The HX-200W produces PTFE rods with exceptional accuracy in diameter and surface finish, making it suitable for critical applications in industries like electronics, automotive, and chemical processing.

- Consistency and Reliability: The machine ensures consistent output, minimizing production downtime and defects in PTFE rod quality.

Leave A Comment

You must be logged in to post a comment.