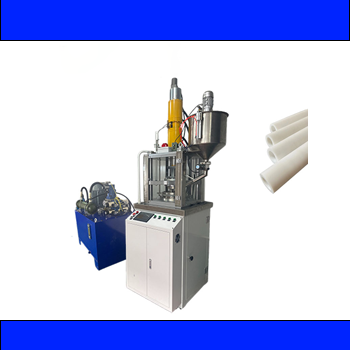

A Multiple PTFE Tube Ram Extrusion Machine is a specialized equipment used for the production of PTFE (Polytetrafluoroethylene) tubes. These machines are designed to extrude PTFE material into various tube sizes and shapes, which are widely used in industries such as pharmaceuticals, chemicals, and electronics.

Function and Working Principle

The primary function of a Multiple PTFE Tube Ram Extrusion Machine is to transform PTFE powder or paste into a tube form through a ram extrusion process. The machine utilizes a ram, or plunger, to push the PTFE material through a heated barrel and die, where it is shaped into a tube. The extrusion process is highly controlled to ensure uniformity in the thickness and length of the tubes.

Features and Benefits

One of the key features of the Multiple PTFE Tube Ram Extrusion Machine is its ability to produce multiple PTFE tubes simultaneously. This increases production efficiency and allows for the creation of tubes with varying dimensions. The machine typically offers precise temperature control, allowing the operator to adjust the heat to suit different types of PTFE material.

Applications

These extrusion machines are commonly used in industries that require high-performance, chemically resistant tubes. Common applications include electrical insulation, medical devices (such as catheter tubes), and components in chemical processing systems where high durability and heat resistance are needed.

Conclusion

In conclusion, the Multiple PTFE Tube Ram Extrusion Machine is an essential tool for producing high-quality PTFE tubes in various industries. Its advanced design and capabilities make it crucial for high-volume production of durable, resistant, and versatile PTFE tubes.

Leave A Comment

You must be logged in to post a comment.