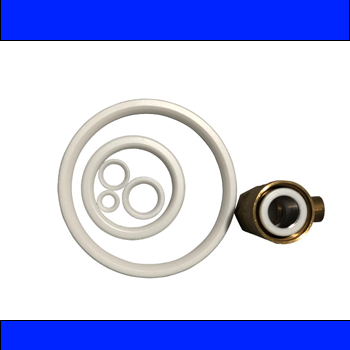

A PTFE (Polytetrafluoroethylene) gasket for a ball valve is a sealing component used to ensure a leak-free connection between the ball valve and the piping system. PTFE is a high-performance polymer known for its excellent chemical resistance, low friction, and high thermal stability, making it an ideal material for sealing applications in various industries, such as chemicals, pharmaceuticals, and oil & gas. PTFE gaskets are typically used in ball valves to prevent leakage of fluids or gases and to provide a reliable seal under different operating conditions.

Working of PTFE Gasket in Ball Valve

The PTFE gasket functions by filling the gap between the ball valve’s flanged connections, creating a tight seal that prevents any leakage of media (liquids or gases). When the valve is closed, the PTFE gasket is compressed between the valve body and the valve seat. This compression ensures that the gasket forms a perfect seal, preventing any fluid from escaping. Due to the material’s high chemical resistance, the PTFE gasket can withstand exposure to harsh substances, including acids, alkalis, and solvents, without degrading or losing its sealing properties.

Advantages of PTFE Gaskets in Ball Valves

The PTFE gasket offers several advantages, such as:

- Chemical Resistance: PTFE gaskets are highly resistant to most chemicals and corrosive substances.

- High Temperature Tolerance: They can handle a wide range of temperatures, from low to high extremes.

- Durability: PTFE gaskets maintain their integrity over time, ensuring long-term reliability and performance.

- Non-stick Properties: PTFE’s non-stick nature reduces friction and wear on valve components.

Thus, PTFE gaskets play a crucial role in maintaining the efficiency and safety of ball valves in various applications.

Leave A Comment

You must be logged in to post a comment.