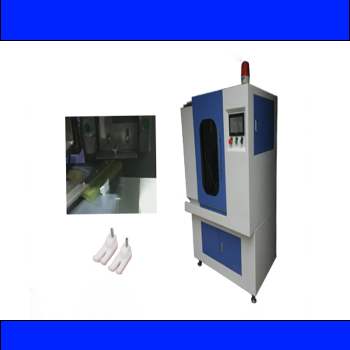

A PTFE (Polytetrafluoroethylene) presser foot molding machine is a specialized piece of equipment used in the manufacturing of presser feet, particularly for sewing machines, made from PTFE material. This machine is designed to mold PTFE into specific shapes and sizes, ensuring high precision and durability in the production of sewing machine components.

Function and Purpose

The primary purpose of a PTFE presser foot molding machine is to create presser feet from PTFE, a highly durable, heat-resistant, and low-friction material. PTFE presser feet are favored in applications where smooth fabric handling and high resistance to wear are required, such as in industrial sewing, textile production, and heavy-duty sewing tasks. The molding machine ensures that the presser feet are accurately formed, meeting the precise specifications necessary for optimal performance.

Working Process

The PTFE presser foot molding machine operates by heating and molding PTFE resin into the desired presser foot shape. The material is first melted and then injected into molds, where it cools and solidifies into the final product. This process ensures that the presser feet have the required physical properties, including strength, non-stick properties, and smoothness, which help prevent fabric from sticking or bunching during sewing.

Advantages of PTFE Presser Foot Molding Machines

These machines offer several advantages, including high precision, speed, and the ability to produce large volumes of presser feet. PTFE’s unique properties, such as its high chemical resistance and low friction, make it an ideal material for presser feet, especially in demanding sewing applications.

Conclusion

The PTFE presser foot molding machine plays a crucial role in producing high-quality, durable, and precise presser feet for industrial sewing. Its ability to mold PTFE into specific shapes ensures optimal performance in various textile and sewing applications.

Leave A Comment

You must be logged in to post a comment.