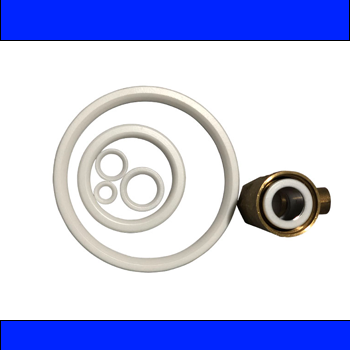

PTFE (Polytetrafluoroethylene) gaskets are versatile sealing components made from a synthetic polymer known for its unique properties. These gaskets are commonly used in various industries to prevent leakage and ensure the integrity of seals in high-performance applications. Due to their exceptional chemical resistance, high-temperature tolerance, and low friction, PTFE gaskets play a crucial role in a wide range of demanding environments.

Applications in Industrial Sealing

One of the primary uses of PTFE gaskets is in industrial sealing applications. These gaskets are widely employed in the oil and gas, chemical processing, pharmaceutical, and food industries, where they provide reliable sealing between two surfaces. PTFE gaskets can withstand harsh chemicals, high pressures, and extreme temperatures, making them suitable for sealing tanks, pipes, valves, and flanges.

Benefits in Harsh Environments

In industries dealing with aggressive chemicals or high-pressure systems, PTFE gaskets provide essential protection against leaks. PTFE’s resistance to acids, alkalis, and solvents ensures that the gaskets maintain their sealing integrity even when exposed to corrosive substances. Additionally, PTFE gaskets can function effectively in extreme temperatures, from cryogenic to high-heat conditions, making them ideal for various thermal processes.

Use in Food and Pharmaceutical Industries

PTFE gaskets are also widely used in the food and pharmaceutical industries due to their non-toxic, non-contaminating nature. Since PTFE does not interact with food or medicine, it is a safe and reliable choice for seals in systems that require high sanitation standards, such as food processing equipment, pharmaceutical manufacturing, and sterile environments.

Conclusion

Overall, PTFE gaskets are invaluable in applications requiring high chemical resistance, temperature tolerance, and performance reliability across various industrial sectors.

Leave A Comment

You must be logged in to post a comment.